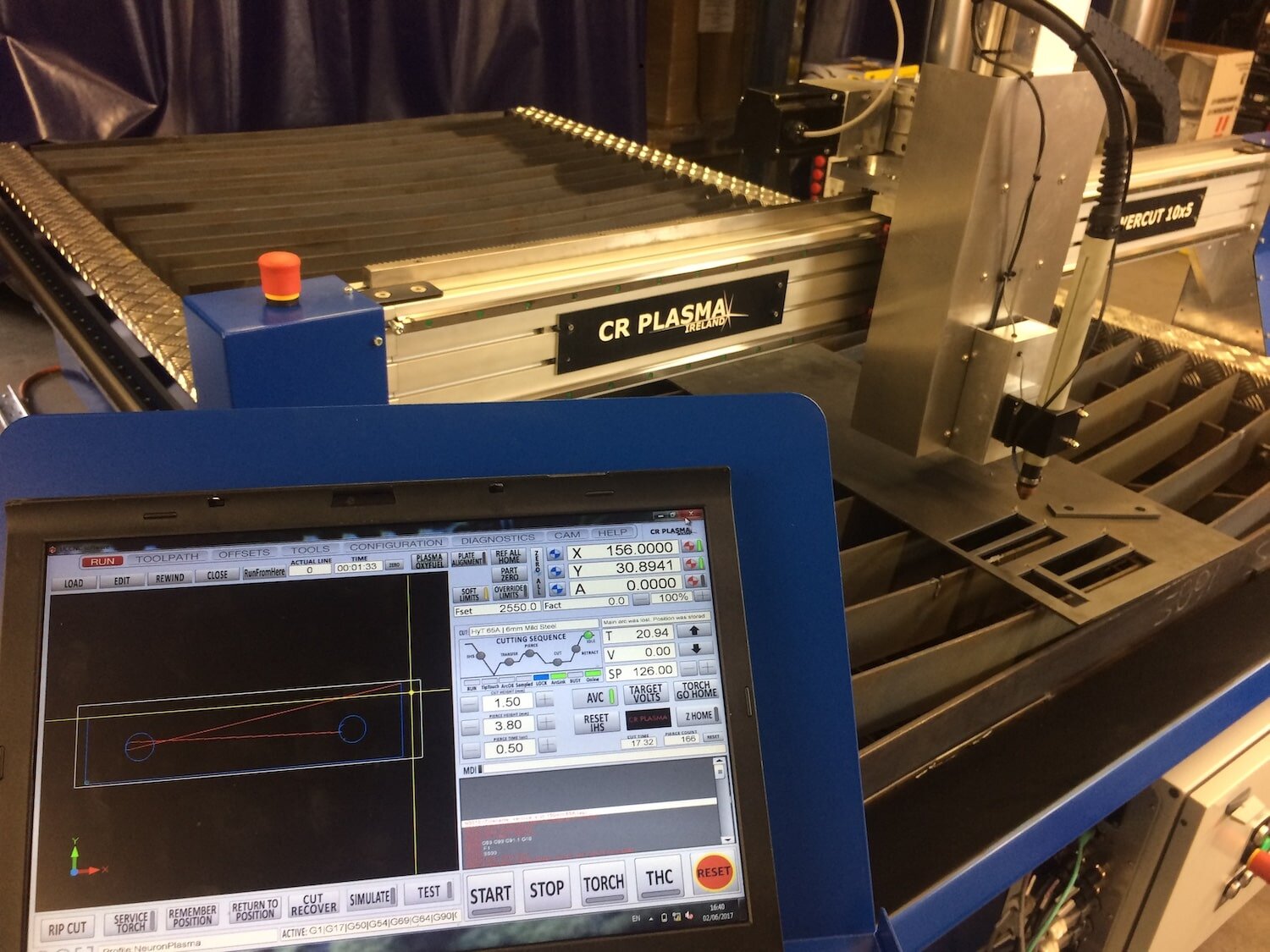

The POWERCUT 10 × 5 Plasma Cutter

Overview

The POWERCUT 10x5 in the CR PLASMA range is the most popular and most widely used platform we offer. The POWERCUT 10x5 has 3300mm x 1530mm of working torch travel allowing full 3000 x 1500mm sized sheets to be fully profiled on the machine. The system is offered with Hypertherm PMX air plasma systems as standard, can be offered with Thermal A40/A60i series of torches, and due to the fact that all systems are fully integrated by us into our controller with a machine-specific calibration - essentially any power source can be integrated.

The standard machine is offered with a PMX 125A system from Hypertherm. This specification of the machine will pierce and cut up to 25mm steel plate.

The CR PLASMA range of machines all have the same fundamental basis as the core machine and control system. All our machines run on HIWIN rails aligned meticulously to the aluminium lengths forming the basis of the long axis motion. All machines are driven by precision ground Gambini rack and pinions. All machines run our own Z-axis torch post lifter and the CR height controller.

This CNC plasma cutter is the base model for our other more specialised CNC plasma cutters:

• High Definition POWERCUT 10x5 CNC Plasma Cutter

• The 4000×2000 Portal Plasma Cutter

• The 6000×2000 Portal Plasma Cutter

• The POWERCUT Ducting Plate Rider Machine

Features

All POWERCUT 10 x 5 CNC plasma cutting machines are supplied as standard with (click to expand) …

Heavy-Duty Steel Downdraft Table

The POWERCUT 3 x 1.5 is built upon a 1000kg steel carcass with a mechanically actuated downdraft table. There are now complex air-driven actuation systems. the movement of the CNC table simply opens and closes the downdraft zones as it moves through the table. Simple, effective, reliable.

XY CNC Drive System

Coming from a CNC router background with over 10 years in automotive applications in CNC routing prior to its adoption into the CR PLASMA range - the XY CR plasma drive system is a tried and tested system now for well over 20 years in plasma use. All drive systems are precision aligned with dial gauges to known datums

Twin-Pinion Anti-Backlash Bearboxes

The machines run a twin pinion, specially designed, anti-backlash gearbox resulting in years of backlash-free operation. The gearboxes are also very straightforward to remover service and refit. The racks and pinions are Gambini ground racks and pinions sourced from the EU. We do not cut cost corners on OEM parts.

Torch Post Z-Axis System

The machines run a Z-axis lifter system designed to eliminate dust/smoke/debris from entering the Z-axis ballscrew and rail system. The covers have a contraflow design resulting in a very clean and reliable Z-axis ballscrew and rail system.

CNC controller

All our CNC controller systems are supplied in collaboration with StoneyCNC resulting in over 10 years of experience in CNC control of CNC routers and CNC plasma systems. With over 500 CNC systems in the EU between StoneyCNC and CRPLASMA, the POWERCUT has a vast degree of experience built into its design.

Height Controller

The CNC controllers run a dedicated height control card solely controlling the Z-axis. Our machines maintain height control to within 0.5 volts and perform as well as any of the other OEM supplied height controllers on the market.

Auto Squaring

The controllers have auto squaring as standard. The controller has left and right-hand side homing sensors. when the machine is asked to reference itself on power-up. the left and the right-hand gearboxes look for their own sensors and home square. Therefore if the machine gets a knock or gets pushed out of the square when powered off, a simple re-reference will square up the bridge to the long axis.

Cut Recovery

All controllers have a cut recovery feature as standard where if the plasma loses its arc, the controller is notified, and the operator can initiate a cut recovery which will restart the job exactly where the arc was lost. CR cur recovery allows for very efficient processing of nested production runs allowing the operator to recover from an issue.

Go-To Position

Go-to position was a game-changer when introduced, it allows the operator to jog to a specific location in an already partially cut nest, and to snap the controller exactly to where a cut recovery is needed. GO TO POSITION along with Cut Recover means there are almost no instances where an operator cannot recover a part that has had an issue during cutting in a nest.

Laser Alignment

All machines have a laser pointer to allow the operator to align the X Y Zero location on any location on the table to set the X Y origin. The laser pointer also allows for an easier visual setup of plate alignment when aligning the next to a sheet of steel loaded at an angle.

Plate Alignment

All machines come with plate alignment that allows the operator to use the laser pointer to align the controller to the sheet if the sheet is loaded at an angle. simply point the laser at 2 locations on the left-hand edge of the loaded sheet and the controller will align the nest to the sheets exact angle.

Rip Cut

All our machines allow for rip cutting - where the operator can easily cut off a section of scrap steel after a part or parts have been cut. Put torch on the start point. set the distance and direction. and the plasma will cut off the offcut as instructed.

Interface Controller

All of our machines run with a high spec Windows 10+ PC. Passively cooled, industrially specified, and with an Intel i5 processor, 4GB of RAM and a 128GB SSD hard disc. the PC spec is high and therefore larger nests can be processed with ease and speed when compared to other smaller power dedicated controllers use in other machines.

Remote Support

After-sale support has been a core pillar for us. All machines are supplied with a high spec PC as the controller. All PC’s have a spare LAN connection for wired network connection (internet or server) and all machines have a WIFI card to allow for internet connection. The result is a CR PLASMA technician can get into your machine as long as you have an internet connection.

Technical Specifications

These are the technical specifications of the POWERCUT 10x5 Plasma Cutter System:

Machine travel … 10 foot x 5 foot travel (3000 x 1500mm)

Machine footprint … 4000 x 2000 x 2000mm

Machine weight … 1500KG

Drive system XY … Anti-backlash dual-pinion rack and pinion

Drive system Z-axis … Ballscrew drive system

Drive motors … High voltage stepper motor drive system

THC system … Fully adaptive Torch Height Control system fitted to the plasma

Machine table … Multi zoned mechanically activated downdraft table

Videos of the POWERCUT 10×5 Plasma Cutter

Here are some great videos showing the POWERCUT plasma cutter range in action.

10mm Mild Steel being cut on the POWERCUT

Watch here as brackets for a fabrication job are cut from a 10mm mild steel plate.

6mm Mild Steel cut on the POWERCUT

Watch here for some smaller brackets being cut on the POWERCUT machine out of 6mm mild steel.

Sheet steel signage with the CR plasma CNC cutting machine.

See here for text cut out of steel sheet for signage with the CR plasma CNC plasma cutting machine.

Datum Features in Steel Flanges

Watch here for some CR Plasma CNC cutting of steel flanges with circular features in the steel profile.

10mm Mild Steel Brackets

Watch here for some CR Plasma CNC plasma cutting of steel brackets in a 10mm plate.

POWERCUT Edu CNC Plasma

Watch here for some CR PLASMA CNC cutting on the Educational spec CR PLASMA Edu series.

“We knew we needed some automation in our workshop and the CR plasma machine has really stood up to the test of steel plasma cutting in a production environment. From our own jobs to outsourced work the plasma cutting system has been a huge boost to productivity.”

CNC Plasma Cutter Tables for Sale

As a manufacturer of CNC plasma cutter tables, we would like to invite you to contact us for support in selecting the perfect CNC plasma cutter for your needs. We offer extensive pre/post-sales support as well as machine modifications and customisations if required. We also offer professional training services to help you maximise the use of your new CNC plasma cutting machine.

Used CNC Plasma Cutting Tables for Sale

As a natural result of our operations offering CNC plasma cutting services we from time to time decommission CNC plasma cutting tables and put these used CNC plasma cutting systems up for sale. If you are interested in potentially buying one of our used tables, please contact us and we will notify you when a suitable machine becomes available.